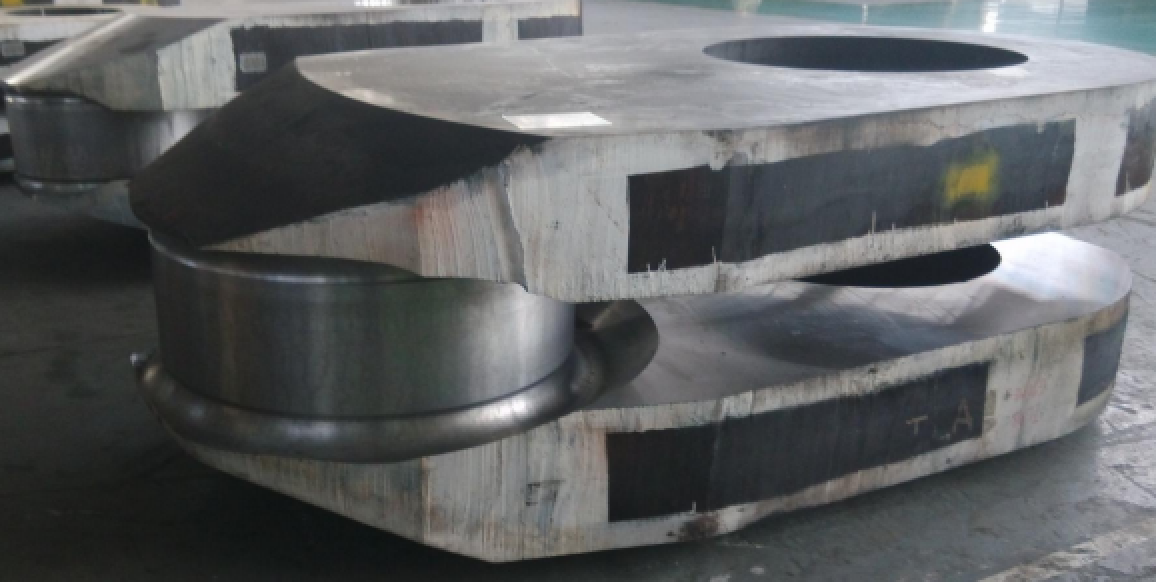

Forging is the collective name of forging and stamping. It uses the anvil block, hammer head, punch of forging machinery or through the die to increase the pressure on the blank, and then produces plastic deformation to obtain parts of the required size and shape. In the forging processing, the blank as a whole will be significantly deformed, there will be a lot of plastic flow; in the stamping process, the blank is usually formed by changing the spatial position of the area of each part, and there will be no plastic flow with a large distance inside. Characteristics of Forging Parts 1. Forging can change the metal structure and improve the metal performance. After hot forging of the ingot, the original cast holes, looseness, and microcracks are compacted, and the structure is broken, so that the grains become finer; at the same time, the uneven distribution and segregation of the original carbides are changed, and the organization is uniform., Dense, good performance forgings. 2. Forging is to make the metal plastic flow and make the required workpiece. After the metal material is subjected to the external force plastic flow, the volume will not change, and the metal always flows to the place where the resistance is small. 3. Forging can improve the internal quality of forgings, mainly to improve its mechanical properties (toughness, strength, fatigue strength, plasticity) and reliability. More rigorous and extensive nondestructive testing of forgings. 4. The size of the forging is accurate, which is conducive to the organization of mass production. Die forging, stamping, extrusion and other applications to form a stable die, accurate size.

2023/04/04

Advantages and Disadvantages of Forging Compared with Casting in Forging Plant

Through their own forging can eliminate the metal in the smelting process can produce as-cast loose and other defects, optimize the micro-economic organization management structure of enterprises, but also because the information to preserve the integrity of the metal flow line, forging mechanical system performance research is generally better than the same material castings. In addition to the relatively simple shapes of rolled plates, profiles or weldments, forgings are mostly used for the important influencing parts with high load and severe working environment conditions in related construction machinery.

2023/07/13

The difference between forging and building

To build, that is, to make, to create. It can be specific things, such as gold and silver, jewelry, weapons, etc., or abstract concepts, such as spirit, culture, brand, etc. Create a word that focuses on the determination to create things, the quality of things, and the strength of the manufacturing methods used.

2023/08/21

Large forging factory tells the main characteristics of large forging parts

Large forging factory tells the main characteristics of large forging parts

2023/09/18

Advantages and Disadvantages of Forging Compared with Casting in Forging Plant

Through their own forging can eliminate the metal in the smelting process can produce as-cast loose and other defects, optimize the micro-economic organization management structure of enterprises, but also because the information to preserve the integrity of the metal flow line, forging mechanical system performance research is generally better than the same material castings. In addition to the relatively simple shapes of rolled plates, profiles or weldments, forgings are mostly used for the important influencing parts with high load and severe working environment conditions in related construction machinery.

2023/10/10